·Prevention of Rail Side Grinding

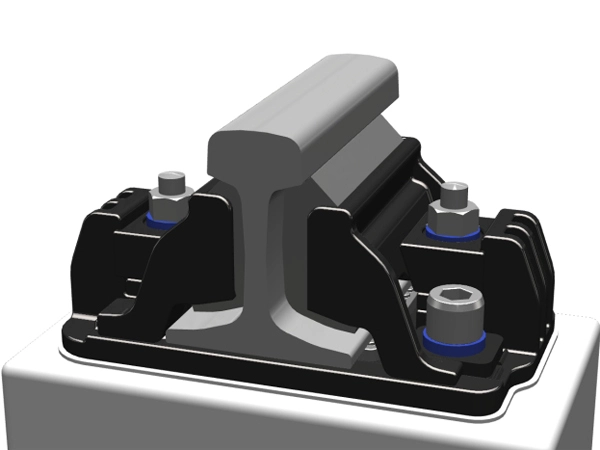

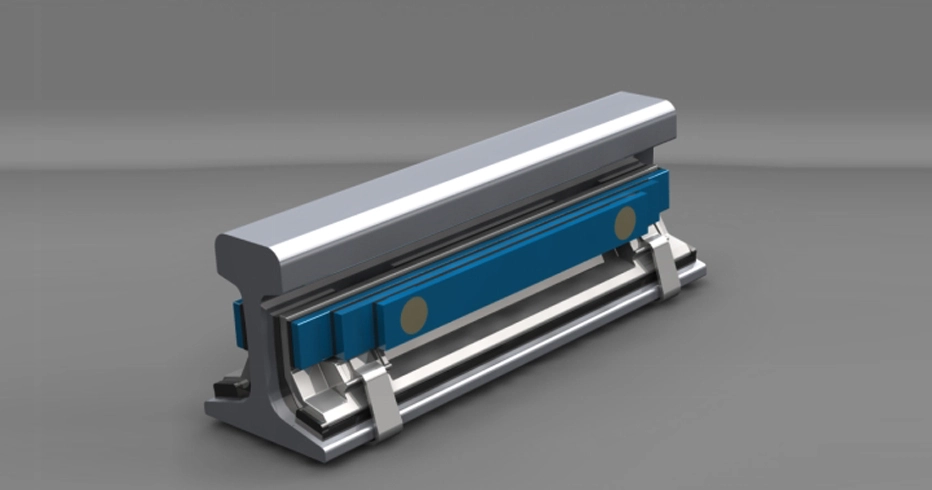

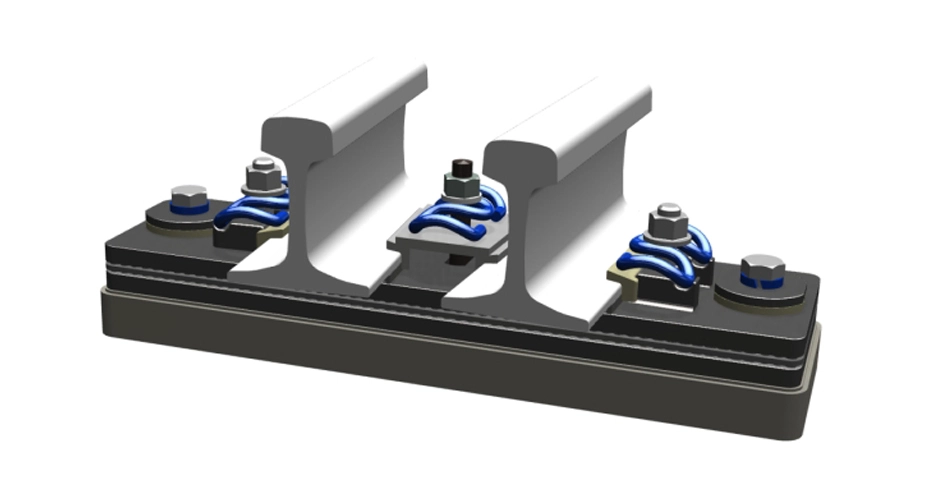

Compared with the traditional plate rubber support block, it can effectively prevent the occurrence of rail side grinding at the bend, with large lateral rigidity and strong gauge-keeping ability.

·Strong Vertical Limit and Rail Smoothness

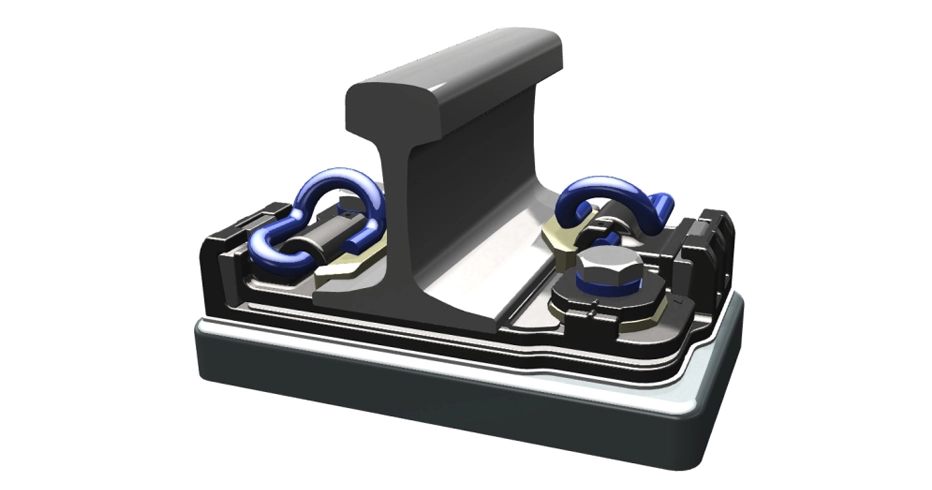

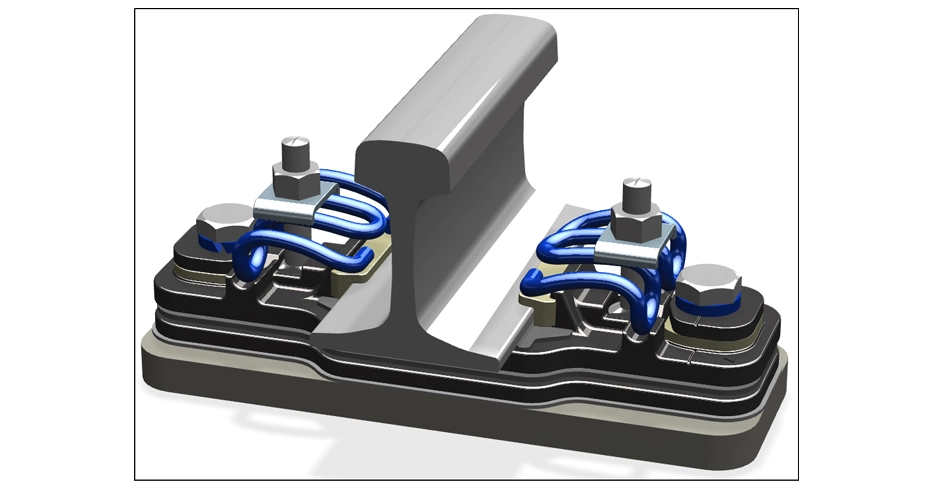

Strong vertical limit and rail smoothness: L-type rubber support block on the rail foot forms a buckling (similar to the buckling effect of the elastic bar), which effectively prevents the occurrence of rail unevenness, realizing anti-loosening in high-twisting.

·Anti-Loosening Safety Design

Anti-loosening safety design: the anti-loosening bolt locks the positioning block, preventing the positioning block from loosening due to train vibration during long-term operation, and eliminating the safety risks caused by the positioning wedge loosening or even pulling out.

·Adjustable Clamping Force

The clamping force is controllable and stepless adjustable: through the positioning design of the locking bolt, the clamping force of each set of fasteners is ensured by the adjustment gasket of different thicknesses, which can realize the adjustment of clamping force of any degree.

·Adjustable Clamping Force

Convenient and quick installation: the tools used in the construction and installation of anti-loose high-torque and high-damping fasteners are the same as those used in ordinary fasteners, without special tools (abandoning hydraulic tools weighing up to 25Kg), and the installation and maintenance are fast and convenient.

EN

EN

jp

jp  ko

ko  fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  tr

tr