Air-cooled heat exchangers are widely used in power generation, chemical processing, and oil and gas industries to remove heat from industrial processes. The operating principle of an air-cooled heat exchanger is based on natural convection whereby a fluid circulating through a series of metal tubes is cooled by air flowing over the tubes, thereby transferring the heat from the fluid to the air.

Air Cooler Structure Type

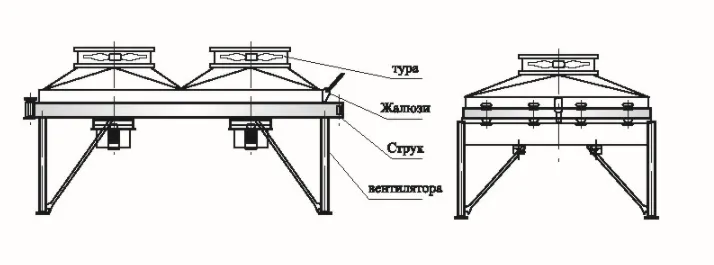

Horizontal Forced-draught Air Cooling

The tube bundle is located on the exhaust side of the fan, which facilitates maintenance and overhaul, while making fan motor always in a cool air environment. It is suitable for the system with high temperature of process medium, and can effectively prolong the service life of equipment. This design is a classic example of a forced draft air cooler.

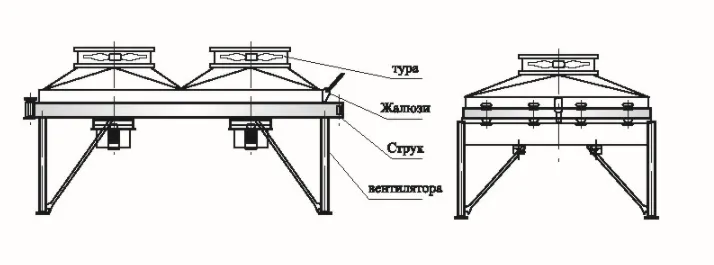

Horizontal Induced-draft Air Cooling

The tube bundle is located at the suction side of the fan. Because the air duct has a good effect of blocking sunlight, wind, rain and snow on the heat exchange fins, the induced-draft air cooler has a stable heat exchange performance. Besides, the induced air cooler has the characteristics of uniform distribution, fewer thermal cycle, less pollution and low noise.

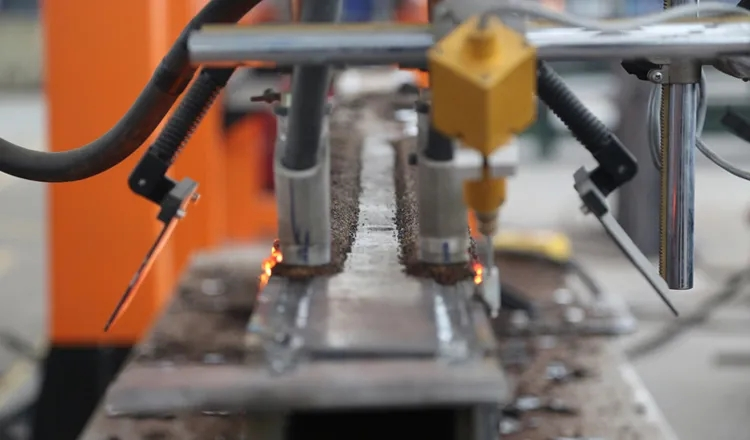

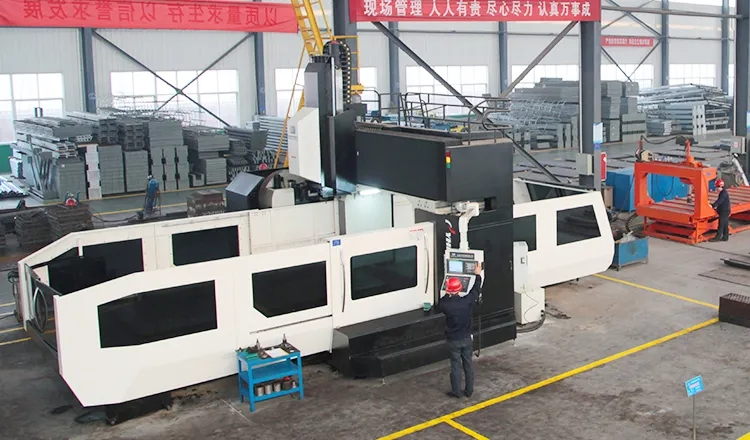

Finned Tube Structure Type

Finned tube is the heat exchange element of air cooler, and its structure type directly determines the performance of the whole heat exchanger. In addition, the connection mode between fins and base tube also has great influence on heat transfer. Fins used for steel tube, aluminum tube or stainless steel tube are mainly made out of aluminum sheet, steel sheet or hot dip galvanized steel sheet. Longhua Group offers a wide array of finned tube types, including L type fin tube, G type fin tube, extruded, welded, and edge tension designs, each tailored to optimize heat transfer efficiency in air-cooled heat exchangers.

EN

EN

jp

jp  ko

ko  fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  tr

tr